TELELIN INSTRUMENTS INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TELELIN INSTRUMENTS INDIA

Barometer

|

|||||||||||||||||||||||||||||||||||||||

Differential Pressure Gauge

| Accuracy | : | ± 2% ofthe FSD (Ascending) |

| Migration | : | Minor from high to low port |

| Range | : | 0-0.25 to 0-70 bar or equivalent range in other units |

| First marking on the scale | : | 20% of the FSD |

| Sensing element | : | Piston |

| Wetted parts | : | Body material, SS 302 spring, Teflon, & ceramic magnet |

| Case material | : | Stainless steel (SS 304) |

| Dial size in inch /mm | : | 2",2.5",3.5",4",4.5", 6"/50, 63, ao, 100, 115, 150 |

| Mounting | : | Direct, front flange & 2" pipe mounting |

| Maximum working pressure | : | 200/400 bar. 200 bar for Alu, Brass & 400 bar for SS body |

| Maximum process temperature | : | 8o°c /175° F |

| Body material | : | Aluminum, Brass, SS 316 & Monel |

| Seals | : | Buna-N, Viton & EPDM '0' rings |

| Window | : | Float glass(Std.), toughened glass & acrylic on request. |

| Connection | : | 1/4" NPT(F) Std. optional 1/4" BSP(F) |

| Porting | : | In-line, rear, bottom |

| Over range protection | : | Up to the max. working pressure from high & low side |

| Protection for gauge & switch | : | IP 65/ NEMA-4 |

Switches (Adjustable in 20·100% of FSD) • 1 or 2 SPSTs with a DIN plug • 1 or 2 SPSTs with a terminal strip • 1 or 2 SPSTs with a built in relay • 1 or 2 SPDTs with a terminal strip • 1 or 2 SPDTs with a DIN plug Options • Glycerine filling • Red follower pointer (except 2" & 6") • Customer logo • Dual scale • Colour band • Filter mesh in (+) connection • Reverse port (Pointer moves from right to lett.) • Descending calibration |

||

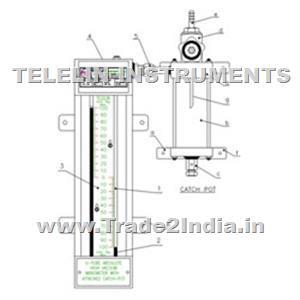

Oil Flow Meter

For Accurate metering of LIGHT, MEDIUM & HEAVY OILS, ORGANIC LIQUIDS & SOLVENTS

This meter falls under the category of Positive Displacement Meters. The Steam of liquid is momentarily interrupted in order to isolate a predetermined volume. This quantity is then discharged and the stream is again interrupted to isolate another similar volume.

The measuring unit of this meter utilizes the mutating piston movement. This movement is similar to the action of a coin which has just been spun and is coming to rest. This design feature maintains the metering accuracy over a wide range of flows and is hardly influenced by variations in viscosity and temperature.

Low headloss is in practice achieved by eliminating reciprocal parts and by allowing sufficient clearance between the piston and the measuring chamber to eliminate friction. In effect the minute clearance between the edge of the piston and the measuring chamber is effectively sealed by a film of liquid.

For line size : ½” to 6”

IMPORTANT FEATURES :

• High accuracy and repeatability with low pressure drop.

• Materials of construction changeable to suit the measured liquid.

• Large metering range for varying viscosity.

• Easy dismantling and cleaning without removing the meter from the pipe.

ACCURACY :

• Standard Meters : +/- 2%

• Special Meters : +/- 0.5%

• Constant viscosity & restricted flow rates can give even better accuracy.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.